- Home

-

Products

- Panels, Networking & Utilities Software

- Detectors, MCPs & Modules

- Alarm (Alerting) Devices

- Power Supplies

- Waterflow Devices

- Spare Parts

- Historic Products

- News

- Downloads

- Tools

- Projects

- About

- Support

- Sitemap

- BPIR

- Contact

News

A Class System for Aspirating Detectors

When building an aspirating detection system it is vital to design for an appropriate level of sensitivity.

For most New Zealand projects we recommend designing to the requirements of European Standard EN 54 part 20, which defines three sensitivity classes: A, B, and C.

An EN 54-20 Class C aspirating system provides standard smoke detection. When a Class C system signals an alarm, you can see and smell the smoke.

Class B systems are more sensitive. They are recommended for applications requiring early fire detection. When the detector triggers an alarm, you can see or smell the smoke, but there won’t be enough to trigger a standard photo-electric smoke detector.

A Class A system gives very early warning of a potential fire situation. This may be appropriate if a fire would cause significant life safety problems, major equipment down-time, or a serious financial loss.

An alarm signal from a Class A aspirating system may indicate that something in the monitored area is smouldering. This could be dismissed as an unwanted alarm, when the aspirating system has done the job it was designed to do: It has detected a potential fire condition.

We recommend that users of Class A aspirating systems should develop a suitable plan for responding to an alarm from the aspirating detector. For example, if the aspirating system is monitoring electrical switchgear, a plant maintenance engineer may need to inspect the monitored equipment.

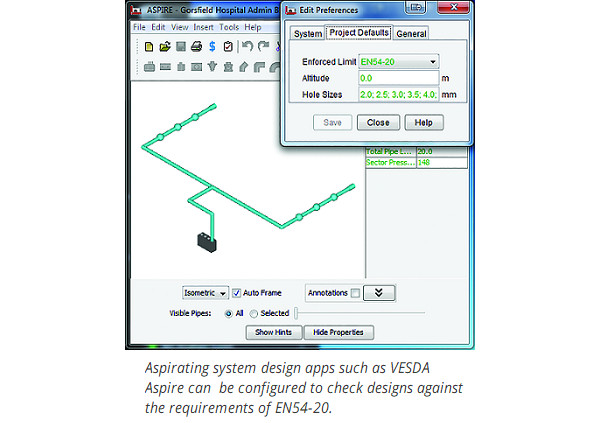

Both VESDA and FAAST have free design applications for their aspirating detectors. These apps can be configured to check pipe network designs to EN 54-20 requirements.

Aspirating smoke detection systems provide elegant solutions to many difficult smoke detection problems. Our customer support team are always keen to help Pertronic customers get the best out of FAAST and VESDA aspirating systems. If you have any questions on aspirating systems, call our support line, 04 567 3229.

Click here to review our range of Aspirating Smoke Detectors

Posted in Technical; Tagged Aspirating Smoke Detection;

Tags

- Alerting Devices

- Amplifiers

- Analogue Addressable

- Audio Distribution Modules

- Cabling

- Conventional Beam Detectors

- Conventional Detection

- Covid_19

- Deluge System

- Detectors

- Drip Loop

- Early Warning Fire Detection

- Equipment Cabinets

- Events

- F100A

- F16e

- F220

- F4

- FAAST

- Fire Alarm Control Panels

- Fire Alarm Mini Panel

- Fire Alarm Panel Keyswitch

- Fire Door Holders

- Fire Graphic System

- Fire Show

- Fire System Management Application

- FireMap

- FireUtils

- Hazardous Area Detection

- Honeywell

- Interfaces and Repeaters

- interns

- IYM

- LED Mimic

- Linear Heat Detection

- Lockdown

- Manual Call Points

- manufacturing

- Net2 Network Systems

- Operations

- OSID - Open Area Smoke Imaging Detection

- Pertronic Offices

- Pertronic Production

- Pertronic SOS

- Product Support

- R&D

- recycling

- Remote Display

- research

- Residential Panel

- Seismic-tested Fire Alarm Panel

- smoke sensor

- Speakers

- Sprinkler FBA

- STEMM

- Strobes

- Suppression

- Takina

- Thermistor Heat Detectors

- Tools

- training

- Unwanted Alarm

- Waterflow Devices

- Weatherproof

- Weatherproof Detectors

- Wiring